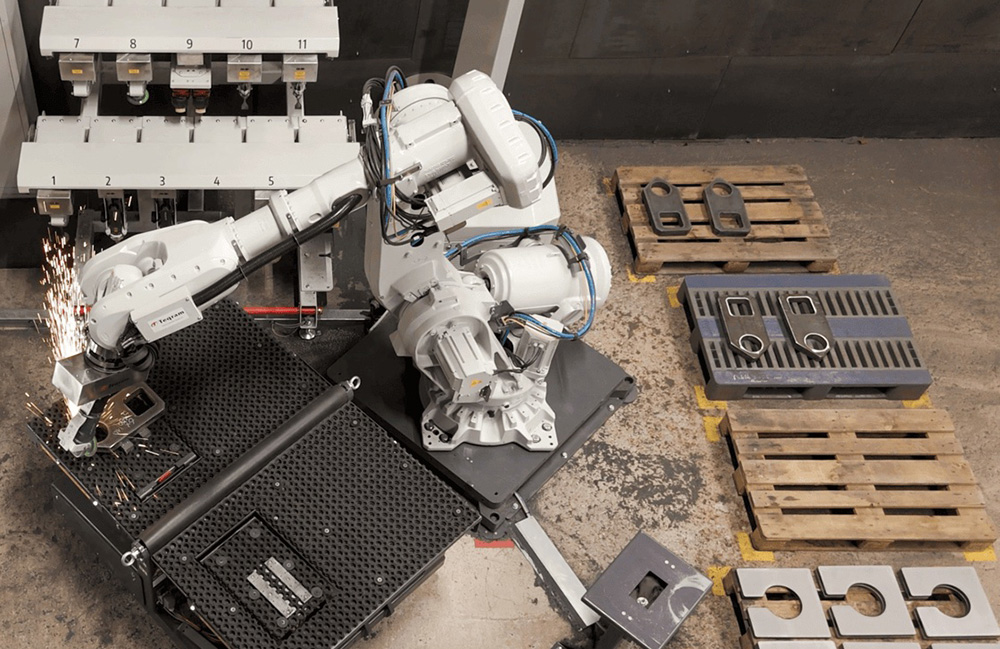

Friedrich Amtenbrink said the EasyGrinder grinding robot has streamlined production processes. | Source: Teqram

Teqram BV this week announced Friedrich Amtenbrink GmbH has deployed its EasyGrinder grinding robot. Since late 2024, the EasyGrinder has been responsible for post-processing up to 1,500 flame-cut and plasma-cut parts per day.

For over 55 years, Friedrich Amtenbrink has provided high-quality steel processing. With a workforce of more than 120 employees, the company said it provides services such as flame, plasma, and laser cutting, in addition to tool steel processing. The Gütersloh, Germany-based company has clients in mechanical and tool engineering, agricultural machinery, automotive supply, and valve manufacturing.

Post-processing is a highly manual process involving four distinct steps with multiple handling operations. Friedrich Amtenbrink said this was both time-consuming and physically demanding for employees.

Teqram brings extensive sheet metal experience

Friedrich Amtenbrink turned to Teqram to automate this demanding process. It said the EasyGrinder robot automates the processing of oxyacetylene and plasma-cut components ranging from 3⁄4 in. to 4 in. (1.9 to 10.1 cm), without requiring complex programming.

Teqram said its robot can efficiently remove slag, break edges, grind bevels, and apply marking for part identification, all without any manual intervention.

This means that after the initial shot blasting process, the EasyGrinder autonomously completes all subsequent steps. For Friedrich Amtenbrink, this not only saves time but also significantly reduces physical strain on the workforce.

Teqram was founded as a spin-off from a sheet metal processing company. It develops and supplies robots for loading and unloading, deburring, leveling, and shot-blasting systems, as well as for de-slagging, grinding, and deburring sheet metal parts.

Equipped with the advanced EasyEye 3D vision system and AI-based controller, Teqram’s robots operate fully autonomously. They automatically recognize pallets, stacks, and product geometries, eliminating the need for manual programming, it said.

Friedrich Amtenbrink increases productivity, lowers headcount

Friedrich Amtenbrink said the EasyGrinder’s capabilities were especially evident in a batch of 400 components, each weighing 110 lb. (49.8 kg), requiring dot-peening before delivery. This task would typically have taken at least two manual shifts.

However, the EasyGrinder completed the entire batch overnight, fully automated. Even heavy laser-cut parts, initially deemed unsuitable for robotic processing, were efficiently handled. While an existing deburring machine could have performed the task, it would have required an employee and an overhead crane for prolonged periods due to the weight.

Thanks to this investment, Amtenbrink said it has not only optimized production but also reduced its reliance on temporary workers. The company replaced three temporary workers with the robot.

“Finding new temporary workers for this demanding and unpopular task was a constant challenge,” said Sultan Nayebi, an operations manager at Amtenbrink. “With the EasyGrinder, we now have a sustainable solution.”

The company’s permanent employees were also impressed. “It feels like we have a new colleague who never tires and takes on the toughest jobs. This allows us to focus on more critical tasks,” one said.

EasyGrinder identifies parts and picks them up with magnetic grippers. It processes parts autonomously using tools from its automatic tool changer. | Source: Teqram